Once again this year we will be present at Host 2023 international trade fair, which will be held in Milan from 13th to 17th October. These five days will serve as significant opportunities to engage with customers and visitors from across Europe, where we can showcase our distinctive solutions, highlighting both our technical innovations and […] weiterlesen... »

Enter our stand at Drinktec fair in Munich and see our solutions for beverage & liquid food industry – Watch the video

These days we are at Drinktec, in Munich, the world’s leading trade fair dedicated to technologies for the beverage & liquid food industry. Thanks to this video you will be able to „enter“ our stand and take a look at the solutions we offer for stainless steel electrical enclosures and aseptic pressure vessels for the […] weiterlesen... »

Auf der Drinktec in München als Spezialisten

Die Drinktec München ist die Fachmesse, an der die bedeutendsten Anbieter von Technologien für die Getränke- und Liquid-Food-Industrie teilnehmen. Dabei werden wir in zwei Segmenten vertreten sein, in denen wir uns als Spezialisten betrachten: Gehäuse aus Edelstahl für Schalttafeln und aseptische Druckbehälter für die Lagerung von Flüssigkeiten, die einer Sterilisationsbehandlung unterzogen werden. Zwei Bereiche, in […] weiterlesen... »

Inoxveneta wird von Magneti Marelli als exzellenter Lieferant von Hydroforming-Rohren für das Jahr 2021 anerkannt.

La San Marco und Inoxveneta: gemeinsam für Innovation in der Tradition des italienischen Espressos

Inoxveneta hat mit La San Marco – einem renommierten Hersteller von professionellen Espressomaschinen – bei der Herstellung einer Hebelmaschine zusammengearbeitet, die von Bonetto, einem etablierten Design Center im Automobilbereich, entworfen wurde. La San Marco ist weltweit führender Hersteller von Hebel-Espressomaschinen und besitzt auch wichtige Patente für diese Technologie. Das Unternehmen hat mit dem Modell LEVA […] weiterlesen... »

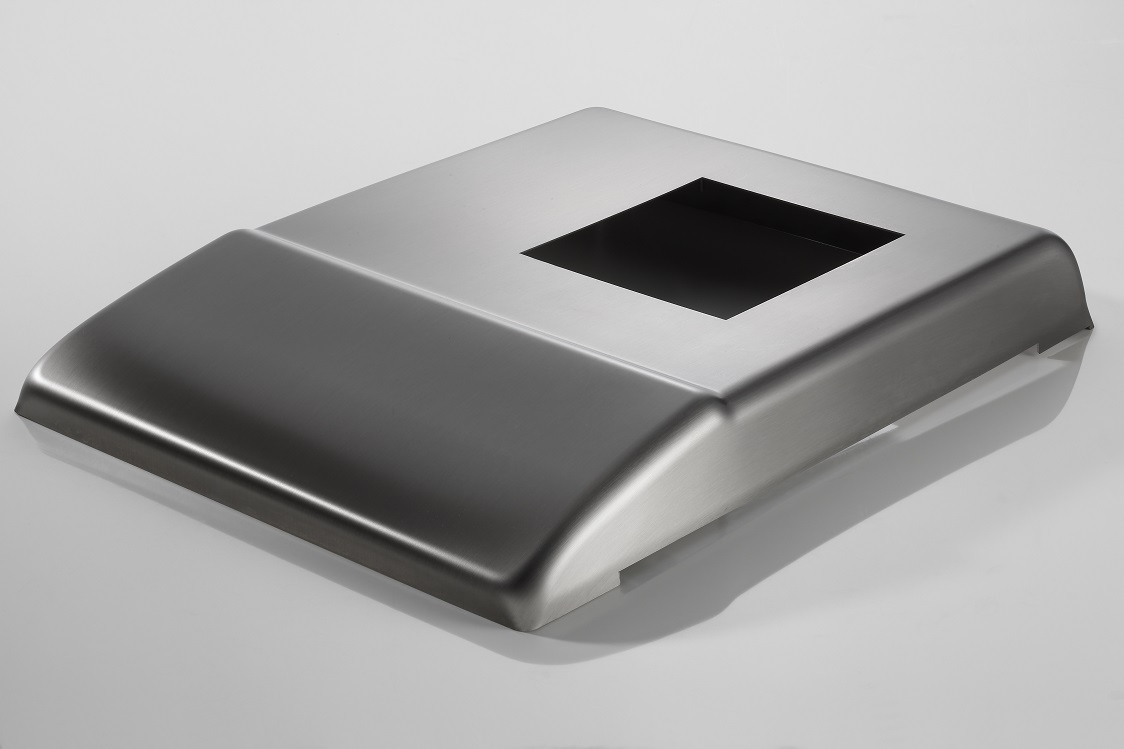

Innovatives Edelstahlgehäuse für professionelle Eismaschinen. Hergestellt mit Hilfe der Hydroforming-Technologie.

Das Bedürfnis unseres Kunden war die Einführung einer neuen professionellen Eismaschine mit innovativen Formen und einem Design, das sich deutlich von dem der Konkurrenz unterscheidet. Im Vergleich zu den zuvor vom gleichen Kunden eingesetzten Fertigungstechnologien hat sich das Hydroforming unter vielen Aspekten als ausgesprochen effizient erwiesen: geringere Werkzeugkosten, mehr Flexibilität in der Produktion, engere Toleranzen […] weiterlesen... »

For the hydroforming of short lenght pipes, one good solution is to hydroform a snake!

Not rarely tube hydroforming regards pipes of short lenght. Due to this short lenght these pipes are of difficult or even impossible processing by hydroforming both for technical reasons as well for the efficiency of production. In order to avoid these difficulties one possible and often used solution is to hydroform a longer tube as […] weiterlesen... »

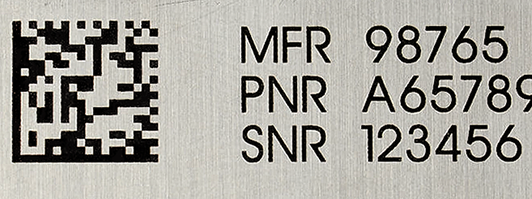

What is it possible to get with a DataMatrix coding on a metal component?

The code DataMatrix is a 2D code, usually in black & white with a rectangular or square shape. It is applied directly on the surface of the component, mainly by means of laser marking. The code DataMatrix contains as much as 4.296 alphanumeric characters within a very small area. Reading of DataMatrix code can be […] weiterlesen... »

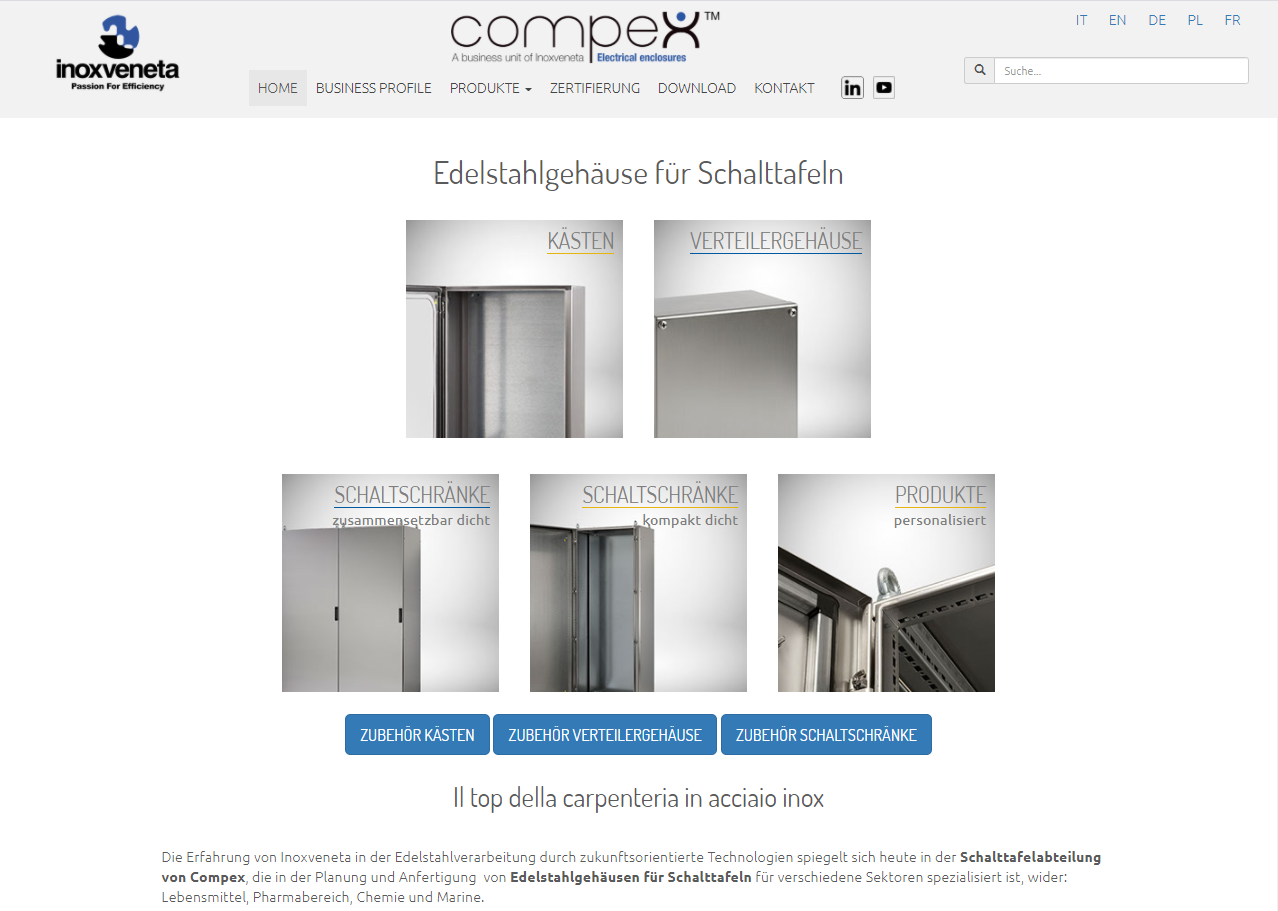

The new Compex web site is on line, now fully dedicated to stainless steel electrical enclosures

COMPEX domain (www.compex.it) is now focused on our stainless steel electrical enclosures. The web site has been designed and built in order to be more than only a shop window of Inoxveneta and of products that we made for the industry of automation but also to be a tool to make easier the interaction with […] weiterlesen... »

Traceability of mechanical parts for the automation industry.

Traceability of complex mechanical parts is coming ever more important in the supply chain of equipments for the automation industry. Traceability means the full tracking of all components and operations involved in the manufacturing process. Inoxveneta adopts an IT system that allows identification of parts since the starting of the production activities, by management of […] weiterlesen... »