Once again this year we will be present at Host 2023 international trade fair, which will be held in Milan from 13th to 17th October. These five days will serve as significant opportunities to engage with customers and visitors from across Europe, where we can showcase our distinctive solutions, highlighting both our technical innovations and […] Read more... »

Enter our stand at Drinktec fair in Munich and see our solutions for beverage & liquid food industry – Watch the video

These days we are at Drinktec, in Munich, the world’s leading trade fair dedicated to technologies for the beverage & liquid food industry. Thanks to this video you will be able to “enter” our stand and take a look at the solutions we offer for stainless steel electrical enclosures and aseptic pressure vessels for the […] Read more... »

At Drinktec in Munich as specialists

Drinktec Munich is the trade fair where the most important suppliers of technologies for the beverage and liquid food industry take part. We will be represented in two segments in which we consider ourselves specialists: Stainless steel enclosures for electrical panels and aseptic pressure vessels for the storage of liquids that undergo sterilisation treatment. Two […] Read more... »

Inoxveneta excellent supplier 2021 of hydroformed stainless steel tubes for Magneti Marelli.

A special sink on cruise ships

The final use is oriented toward cruise ships and our customer was looking for a new design in order to get style, hygiene and functionality. Photos speak by themselves! Hydroforming by Inoxveneta allows to have a sink made of stainless steel for drinking water fountain with characteristics of surface accuracy and finishing as for customer’s needs. […] Read more... »

Innovation & Tradition for the Italian Espresso!

Inoxveneta has been cooperating with La San Marco – the Italian leading brand for the lever-driven machines for espresso – in the realization of a new professional product at the top for its range. The design done by Bonetto Design Center is inspired by the engine V6 of a sporty car. The body is made […] Read more... »

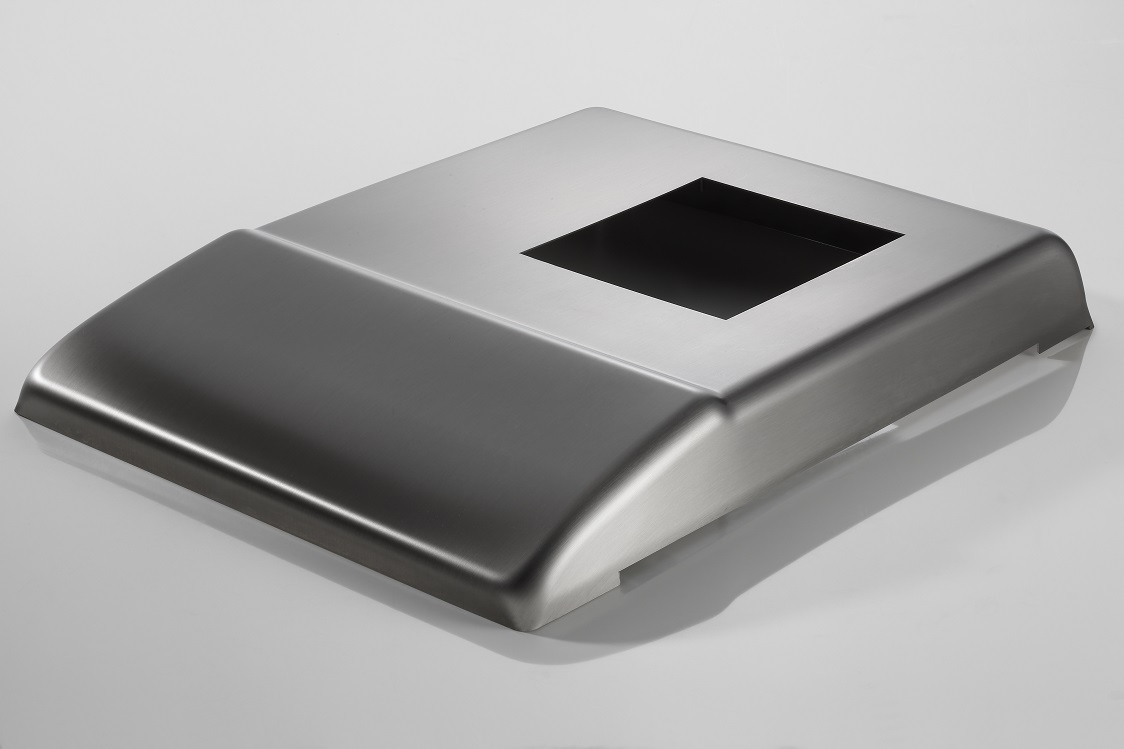

Innovative stainless steel body for professional ice cream maker. Produced by means of hydroforming.

Our customer’s need was to have a new professional machine for ice cream with innovative and attracting shapes, with a very distinctive design in respect of competitors. In comparison to traditional technologies of production used in the industry of these machines, hydroforming of stainless steel sheet turned out as optimal under many aspects: reduced cost […] Read more... »

For the hydroforming of short lenght pipes, one good solution is to hydroform a snake!

Not rarely tube hydroforming regards pipes of short lenght. Due to this short lenght these pipes are of difficult or even impossible processing by hydroforming both for technical reasons as well for the efficiency of production. In order to avoid these difficulties one possible and often used solution is to hydroform a longer tube as […] Read more... »

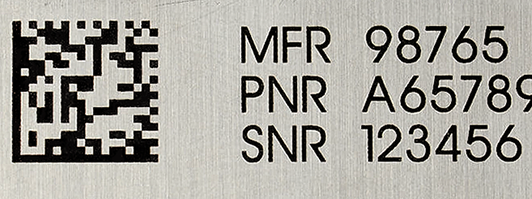

What is it possible to get with a DataMatrix coding on a metal component?

The code DataMatrix is a 2D code, usually in black & white with a rectangular or square shape. It is applied directly on the surface of the component, mainly by means of laser marking. The code DataMatrix contains as much as 4.296 alphanumeric characters within a very small area. Reading of DataMatrix code can be […] Read more... »

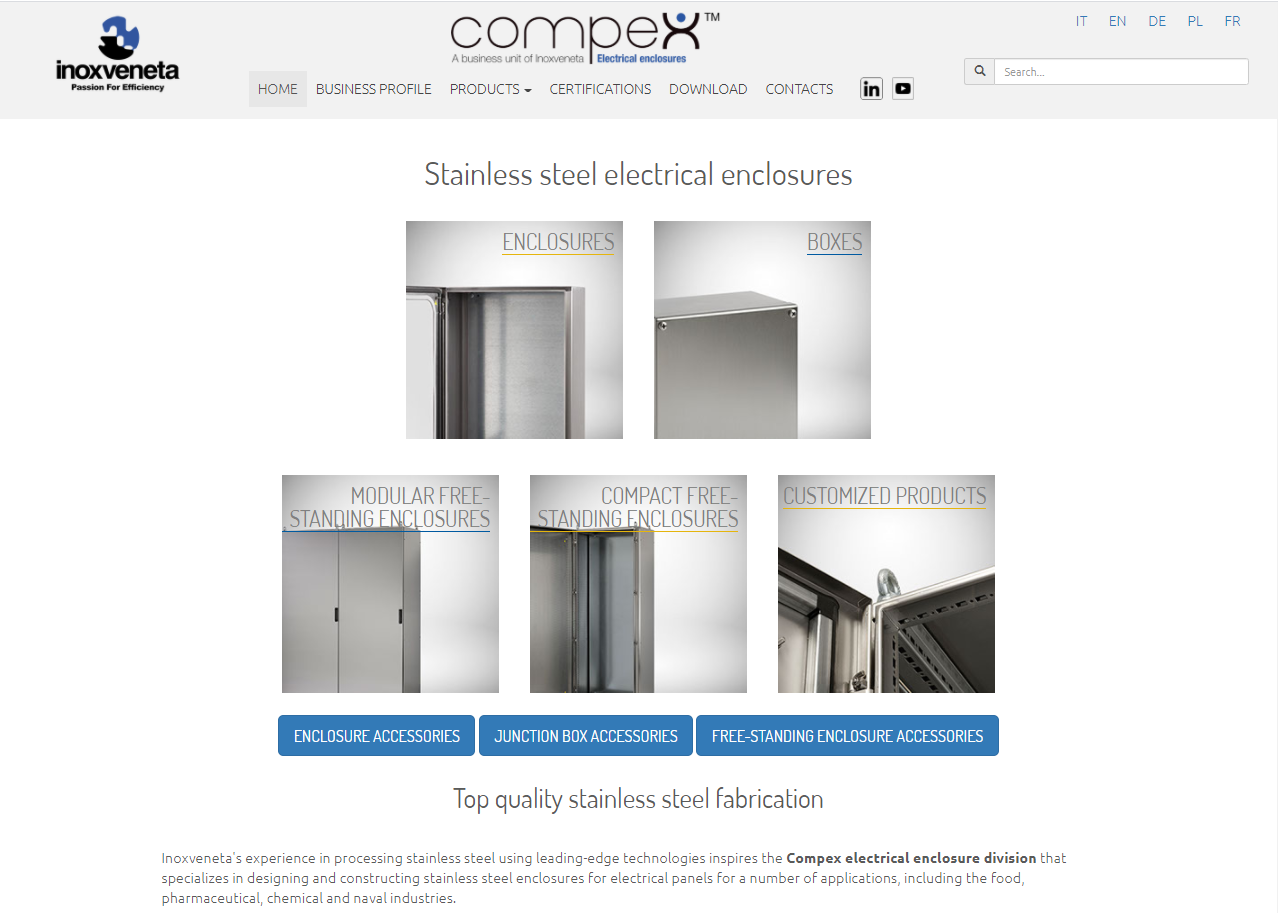

The new Compex web site is on line, now fully dedicated to stainless steel electrical enclosures

COMPEX domain (www.compex.it) is now focused on our stainless steel electrical enclosures. The web site has been designed and built in order to be more than only a shop window of Inoxveneta and of products that we made for the industry of automation but also to be a tool to make easier the interaction with […] Read more... »