Inoxveneta works hard, with competence and professionalism, to the constant updating of technological and organizational processes to provide customers with a competitive advantage, based on innovation and efficiency. We value the customer by integrating our organization in the most advanced Supply Chains.

The stainless steel machining is our world and we are constantly looking for innovative solutions that guarantee the development of competitive and high-performance products. Whatever the field of application may be, we guarantee the best result from the technical, functional and aesthetic point of view.

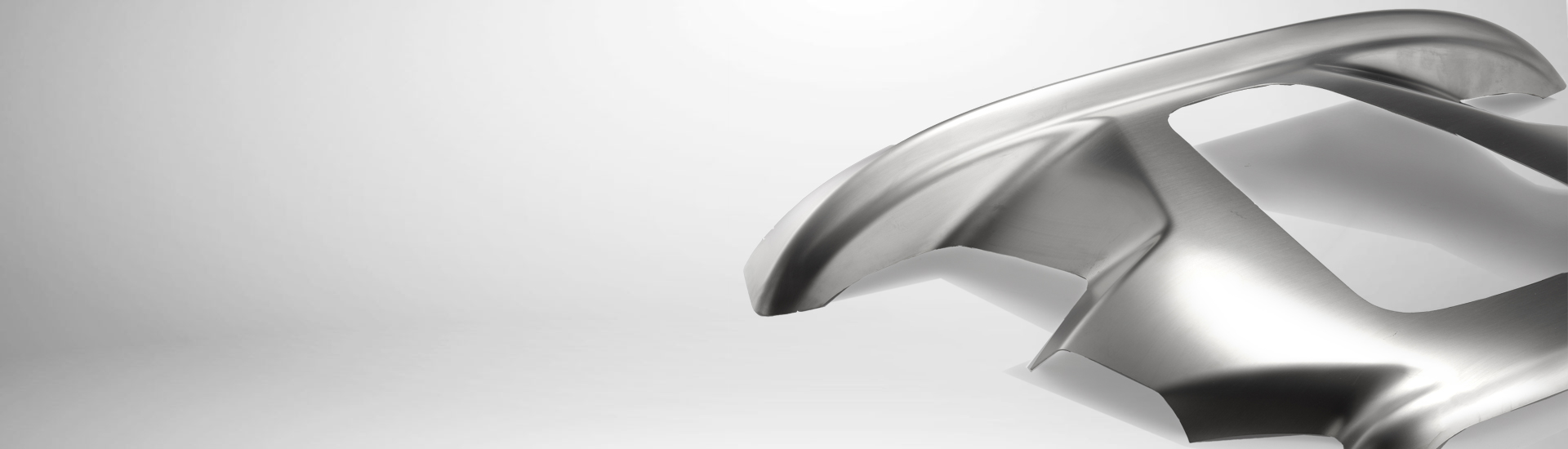

We are precursors in the field of hydroforming. An innovative technological process that allows the sheet metal and stainless steel (and aluminium) tubes processing with great efficiency, making possible forms unthinkable with the conventional technologies.

Design, home appliances and automotive (with the use also of aluminum and titanium) are just some of the industrial sectors in which our applications are diffused. Hydroforming and elastoforming (combined with other technologies such as 3D laser cutting and stainless steel robotic welding) are ideal destination for a growing number of industrial applications.

Our numbers

3 factories

(2 in Vittorio Veneto + in Strzelin PL)

21,200 sq.m.

Covered surface

4

hydroforming systems with up to 7000 tons force

7

2D laser cutting and punching systems

2

3D laser systems

5

welding robots

more than 3,000,000

pieces sold

5%

of turnover invested in R&D annually

more than 10,000,000

of effected product cycles

over 30

export countries

An enterprise that has started over 50 years ago. A history of knowledge, experience, technology and innovation that allows us to serve our Customers.

Inoxveneta Spa incorporating GBF Srl was founded

Alfonso Kratter become CEO side by side with Enrico Favaro

Great development of Total Quality and the computer system

Compex trademark registration. It started the production of stainless steel guides for the professional refrigeration field

The traditional organization of production through processing departments was replaced by the lean manufacturing of product lines

ISO 9001 Certification

Development of Lean Manufacturing and commercial development in the Far East

Installation of the first plant for hydroforming

ISO 14000 Certification

The new factory in Strzelin-Poland started the production. Installation of the third plant for hydroforming.

ISO/TS 16949:2009 Certification specific for the automotive sector (today Inoxveneta SpA is MAQMSR (IATF 16949) compliant).

Installation of the fourth plant for hydroforming. New robotized welding system.

Taylor Made

We have the ambition to sew for each customer, in addition to specific products, a customized service and approach. We offer a flexible and tailor made know how in the field of stainless steel machining.